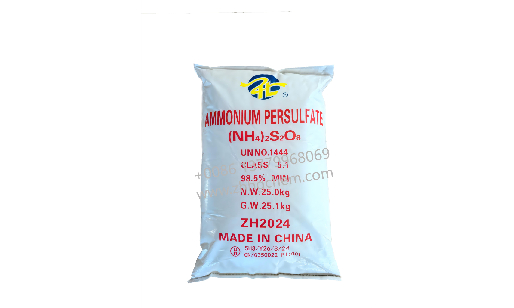

Ammonium persulfate is widely used in polymer chemistry. As an effective polymerization initiator, this white monocrystal plays an important role in multiple industries due to its strong oxidizing property and stability. Its applications include being used as an etchant and cleaner in the manufacturing of printed circuit boards, as a booster in hair bleaching formulations in cosmetics, and as a gel breaker in the oil and gas industry. Although ammonium persulfate is a non-flammable substance, due to its characteristic of releasing oxygen, great caution must be exercised when using it. The following are some precautions for using ammonium persulfate to ensure safety and high efficiency.

Safety Protection: The First Step to Ensure the Safety of Operators

Operators should wear professional personal protective equipment such as protective clothing, gloves, and goggles to avoid direct contact with the skin or eyes. In case of accidental contact, the contaminated area should be immediately rinsed with plenty of clean water, and medical treatment should be sought in a timely manner. Good personal protective measures can effectively reduce the harm of chemicals to health and ensure the safety of workers during the operation process.

Storage Conditions: An Important Factor for Ensuring the Stability of Chemicals

Ammonium persulfate must be stored in a dry and well-ventilated environment, avoiding direct exposure to fire sources, heat sources, and direct sunlight. Meanwhile, it should be avoided to store it mixed with other chemical substances, especially flammable and explosive materials, to prevent dangerous reactions. Regularly checking the temperature and humidity in the warehouse to ensure that the storage conditions are always within a safe range is the key to maintaining the stability of the product.

Operation Specifications: Scientific Operation Is the Guarantee of Safety

Before using ammonium persulfate, operators need to receive professional training and master relevant operating procedures and safety knowledge. Avoid direct contact with reducing substances, such as metal powders, to prevent violent chemical reactions that may lead to accidents. Ensuring that the operation process follows the prescribed steps can reduce safety hazards to a certain extent and improve work efficiency.

Fire Protection Preparation: A Necessary Measure to Prevent Fire Risks

The work area needs to be equipped with corresponding types and quantities of fire-fighting facilities to deal with possible fire risks. Regular fire drills should be carried out and fire-fighting equipment should be inspected to ensure that they can work normally in emergency situations. In the operating environment of hazardous chemicals, having good fire protection preparation can provide a solid guarantee for safe operation.

Attention to Details: Precautions in the Electroplating Process

During the electroplating process, the use of ammonium persulfate must be cautious. When mixed with reducing agents, it may cause violent reactions and generate a large amount of heat and harmful gases. Therefore, the concentration of ammonium persulfate should be strictly controlled. Too high or too low a concentration will affect the electroplating effect. When using it, the requirements of the electroplating process should be followed, and it is forbidden to change the usage methods and dosages without authorization.

Treatment of Waste Liquid: Environmental Protection Responsibilities Cannot Be Ignored

When treating ammonium persulfate waste liquid, it must be done in accordance with environmental protection requirements, and it is absolutely forbidden to discharge it randomly. Reasonably classifying and treating the waste liquid is not only responsible for the environment but also a basic requirement of laws and regulations. Standardizing the treatment of waste can help reduce the negative impact on the ecological environment.

Quality Assurance: High-Quality and Reliable Suppliers

In the production of persulfate series products, Fujian Zhanhua Chemical Co., Ltd., as a professional manufacturer of persulfate series products, is constantly committed to improving product quality and safety management. The company has an annual output of 75,000 tons of ammonium persulfate and is currently implementing the third-phase project, with a plan to achieve an annual output of 125,000 tons in 2025 to further enhance its competitiveness in the global market. The commitment of Fujian Zhanhua Chemical Co., Ltd. is not only reflected in providing high-quality products but also in continuously pursuing technological innovation and safe production to better serve the needs of a wide range of customers.

By understanding ammonium persulfate and following the precautions for its use, its advantages in various fields can be effectively utilized while maintaining safety guarantees. This can not only improve work efficiency but also provide dual guarantees for participants and the environment. Scientific and reasonable usage methods are helpful for achieving more extensive application effects while maintaining good norms for the safe use of chemicals.