Emulsion polymerization is a process method in which monomers are dispersed by emulsifiers in an aqueous phase system and undergo free radical polymerization. It is widely used in fields such as coatings, adhesives, and synthetic rubbers. By forming a stable emulsion system, this process can not only significantly improve the dispersibility of polymers and the uniformity of molecular weight distribution, but also effectively reduce production costs by using water as the medium. Therefore, it has significant advantages in industrial production. In the emulsion polymerization reaction system, the selection of initiators directly affects the polymerization reaction rate, molecular weight regulation, and product properties. Currently, the commonly used initiator systems in industry include persulfates (such as ammonium persulfate, Potassium Persulfate), azo compounds, and redox systems, etc. Among them, due to its unique redox potential (approximately 2.0V vs. SHE) and good solubility in the aqueous phase, Potassium Persulfate (K₂S₂O₈) is particularly suitable for monomer systems that are sensitive to pH values (such as acrylates), and can achieve stable initiation within a wide temperature range. Therefore, in specific emulsion polymerization processes, Potassium Persulfate is often one of the preferred initiators.

Potassium Persulfate (K₂S₂O₈) is a typical strong oxidant with a high valence state. The peroxide bond in its molecular structure endows it with remarkable free radical generation ability. When heated or in contact with a reducing agent, Potassium Persulfate can decompose to generate sulfate radicals. These radicals are highly reactive and can effectively initiate the polymerization reaction of vinyl monomers. It is worth noting that Potassium Persulfate has good stability in a dry state at room temperature and is not easy to decompose. This enables it to maintain its activity for a long time during storage and transportation, reducing the risk of production interruptions caused by the failure of the initiator. In addition, the reaction conditions of Potassium Persulfate are relatively mild, and it can efficiently initiate the polymerization reaction at conventional process temperatures. Compared with other types of initiators, it can reduce production energy consumption, and its mild reaction conditions can significantly reduce the destructive effects on the emulsifiers and stabilizers in the emulsion system. This is very important for maintaining the uniformity of the morphology of polymer particles and the quality stability of the final product.

In the emulsion polymerization process, an ideal initiator needs to meet multiple requirements simultaneously, such as efficient free radical generation, good stability, reaction controllability, and environmental friendliness. The decomposition reaction conditions of Potassium Persulfate are mild and easy to regulate. Production personnel can precisely control the reaction process through the optimization of process parameters, thereby effectively adjusting the polymerization reaction rate and molecular weight distribution. Its decomposition products are mainly sulfate ions and water, and no toxic or harmful substances are produced, fully meeting the green environmental protection standards of modern industry. This dual advantage—both meeting the technical requirements of the polymerization process and complying with environmental protection specifications—has enabled Potassium Persulfate to be widely used in industrial fields such as coatings, papermaking, and adhesives, and has gradually expanded to fields with high safety requirements such as cosmetics, becoming a favored choice of initiator.

Taking the preparation of coatings and adhesives as examples, the stability of emulsion polymerization and the properties of the products directly determine the quality level and market competitiveness of the products. With its efficient initiation performance and mild reaction conditions, Potassium Persulfate can significantly improve the dispersion uniformity of polymers and the adhesion to the substrate, while reducing the environmental load during the production process. In the emulsion system of cosmetics, Potassium Persulfate not only exhibits excellent initiation efficiency, but its low toxicity characteristics also ensure the long-term stability of the emulsion products, fully meeting the stringent requirements of the cosmetics industry for the safety and quality stability of raw materials.

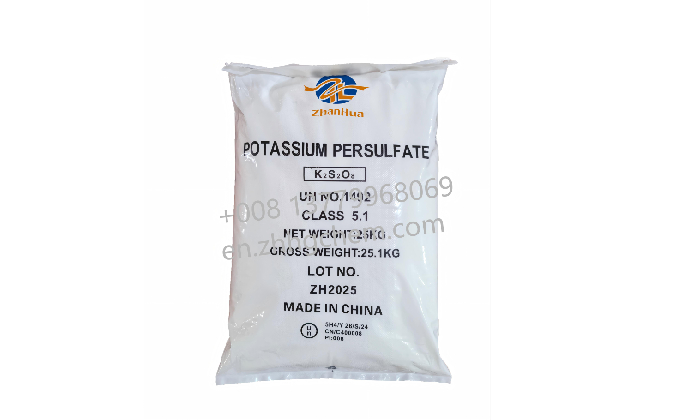

It is worth mentioning that the high efficiency and stability of Potassium Persulfate did not come overnight, but stem from the continuous innovation and technological progress of the enterprises behind it. As a globally renowned manufacturer of persulfates, Fujian ZhanHua Chemical focuses on the research, development, and production of persulfate series products. The Potassium Persulfate produced by it is renowned for its high purity, high activity, and stability. Fujian ZhanHua Chemical not only has a mature production line with an annual output of 12,000 tons of Potassium Persulfate, but is also implementing the third-phase project. In the future, it will achieve an annual production capacity of 30,000 tons, further consolidating its dominant position in the global persulfate field. With its mature technology and complete supply chain system, the products of Fujian ZhanHua Chemical are not only widely used in the domestic market, but also serve more than 30 countries and regions such as Southeast Asia, South America, and the Middle East, becoming an important partner in the field of emulsion polymerization.

From an economic benefit perspective, the high utilization rate of Potassium Persulfate significantly reduce the production costs of emulsion polymerization. Its high-efficiency initiation ability not only shortens the reaction time, but also improves production efficiency, bringing considerable economic returns to enterprises. At the same time, its environmental protection characteristics have also won market competitiveness for enterprises and met the demands of modern consumers for green and environmentally friendly products.

In general, as an initiator for emulsion polymerization, Potassium Persulfate provides strong support for the development of multiple industries with its high efficiency, stability, and environmental protection characteristics. As a globally renowned manufacturer of persulfates, Fujian ZhanHua Chemical provides a reliable solution for emulsion polymerization through continuous technological innovation and strict quality control. The combination of this technology and innovation not only promotes the progress of emulsion polymerization technology, but also provides important support for the efficient and green development of modern industry.