Potassium persulfate, as a vital inorganic oxidizer, finds extensive applications in the chemical industry, with its role in K acid production being particularly prominent. K acid (1-amino-8-naphthol-3,6-disulfonic acid) is a key organic intermediate widely used in dyes, pesticides, pharmaceuticals, and other industries. As a critical raw material in its production, potassium persulfate not only influences product quality but also plays a decisive role in production efficiency. The following explores the application of potassium persulfate in K acid production from multiple perspectives to help readers better understand its importance in chemical manufacturing.

1. Chemical Characteristics and Industrial Applications of K Acid

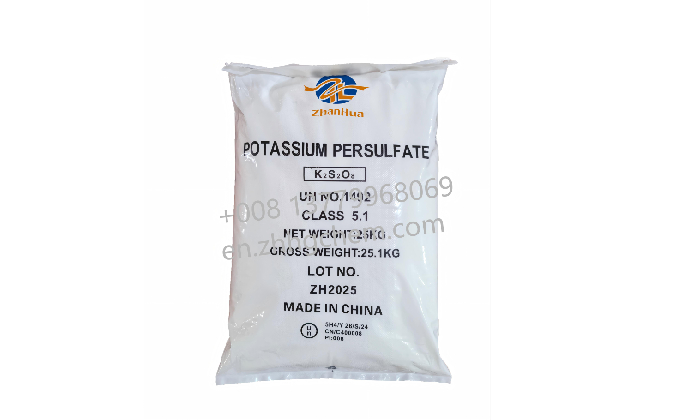

First, understanding the basic properties of potassium persulfate is fundamental to grasping its applications. Potassium persulfate is a colorless or white crystalline powder with strong oxidizing properties, exhibiting good chemical stability under normal temperature and neutral conditions. These characteristics make it an ideal oxidizer for many chemical reactions. In K acid production, the core role of potassium persulfate lies in oxidizing arylamine intermediates or promoting the depth of sulfonation reactions. Compared with other oxidizers, potassium persulfate not only has higher oxidizing power but also reduces over-oxidation side reactions by controlling reaction conditions, thereby improving product purity and quality.

2. Key Properties and Reaction Mechanisms of Potassium Persulfate

In K acid production, the addition of potassium persulfate significantly increases reaction rates, 得益于 (thanks to) its high reactivity in strongly acidic environments, which enables the completion of oxidation processes in a shorter time. Through optimizing reaction conditions, many chemical enterprises have not only improved production efficiency but also reduced energy consumption. For example, reasonably controlling the dosage of potassium persulfate and adjusting parameters such as reaction temperature and acidity can make the reaction more efficient and stable. This optimization not only helps increase K acid yield but also reduces unnecessary by-products, further enhancing the product’s market competitiveness.

3. Core Factors for Enhancing Reaction Efficiency

Of course, the quality of potassium persulfate directly impacts the effectiveness of K acid production. High-quality potassium persulfate typically has higher purity and lower impurity content, ensuring reaction stability and consistency. Conversely, substandard potassium persulfate—such as those with insufficient purity or high impurity levels—may lead to reduced reaction efficiency or even generate by-products that affect product quality. Common impurities like iron ions can catalyze the decomposition of potassium persulfate, reducing the effective oxygen content and slowing reaction rates. Therefore, selecting high-quality potassium persulfate suppliers is crucial for K acid manufacturers. As a high-tech enterprise specializing in persulfate production, Fujian ZhanHua Chemical has gained wide application of its potassium persulfate in K acid production, thanks to its strict quality control system and advanced production processes. Through multi-stage purification, it controls iron content at ≤5ppm, ensuring reaction stability. The stability and efficiency of its products have provided reliable support to many chemical enterprises, making it a trusted brand in the industry.

4. Core Criteria for Supplier Selection

Beyond quality, optimizing the application of potassium persulfate in actual production is another key concern. First, reasonable control of potassium persulfate dosage is fundamental: excessive use increases costs and may trigger unnecessary side reactions, while insufficient use can lead to incomplete reactions and affect product quality. Therefore, manufacturers need to determine appropriate dosages based on specific reaction conditions and equipment performance. Second, optimizing reaction conditions—such as temperature, acidity, and stirring speed—is also critical to enhancing production efficiency. Through experiments and data analysis, enterprises can identify optimal reaction parameters to improve efficiency while ensuring product quality.

The application of potassium persulfate in K acid production not only demonstrates its significant value in the chemical industry but also highlights its unique advantages as an efficient oxidizer. Through in-depth analysis of its basic properties, specific roles in K acid production, and optimized applications, enterprises can better utilize this raw material to enhance production efficiency and product quality. As a professional persulfate manufacturer, Fujian ZhanHua Chemical provides reliable support to global chemical enterprises through its high-quality products and comprehensive service system. Choosing an excellent supplier like Fujian ZhanHua Chemical ensures not only stability and efficiency in production but also a solid foundation for enterprises’ sustainable development. Against the backdrop of continuous development in the chemical industry, the applications of potassium persulfate and K acid will continue to bring new opportunities and challenges, driving further innovation and progress in related fields.