Etching technology, a process of removing specific areas from material surfaces via chemical or physical methods, is widely applied in electronics manufacturing, semiconductor industry, aerospace, and other fields. Since the mid-20th century, etching has evolved from traditional chemical etching to modern precision etching, becoming an indispensable core technology in modern industry. The selection and application of etchants are crucial in this process, and Sodium Persulfate (Na₂S₂O₈), as an efficient and eco-friendly etching-related compound, has emerged as the preferred choice in numerous processes. Its excellent chemical stability and unique properties make it irreplaceable in etching. So, what is the specific role of Sodium Persulfate in etching?

I. Basic Properties and Preparation of Sodium Persulfate

Sodium Persulfate is an inorganic compound with notable oxidizing properties, water solubility, and thermal stability. It decomposes to generate sulfate radicals (SO₄・⁻) under acidic conditions, reacting with various metallic and non-metallic materials to facilitate etching. Physically, it appears as a white crystalline powder, readily soluble in water, and stable at room temperature.

The primary preparation methods include the electrolysis method and chemical synthesis, with electrolysis being widely adopted for its environmental friendliness and high-purity advantages. Fujian ZhanHua Chemical, a global leader in Sodium Persulfate production, employs electrolysis technology to ensure product purity and consistency. The company's strict quality control processes and testing standards further guarantee the high quality of its Sodium Persulfate, setting industry benchmarks.

II. Role of Sodium Persulfate in Etching

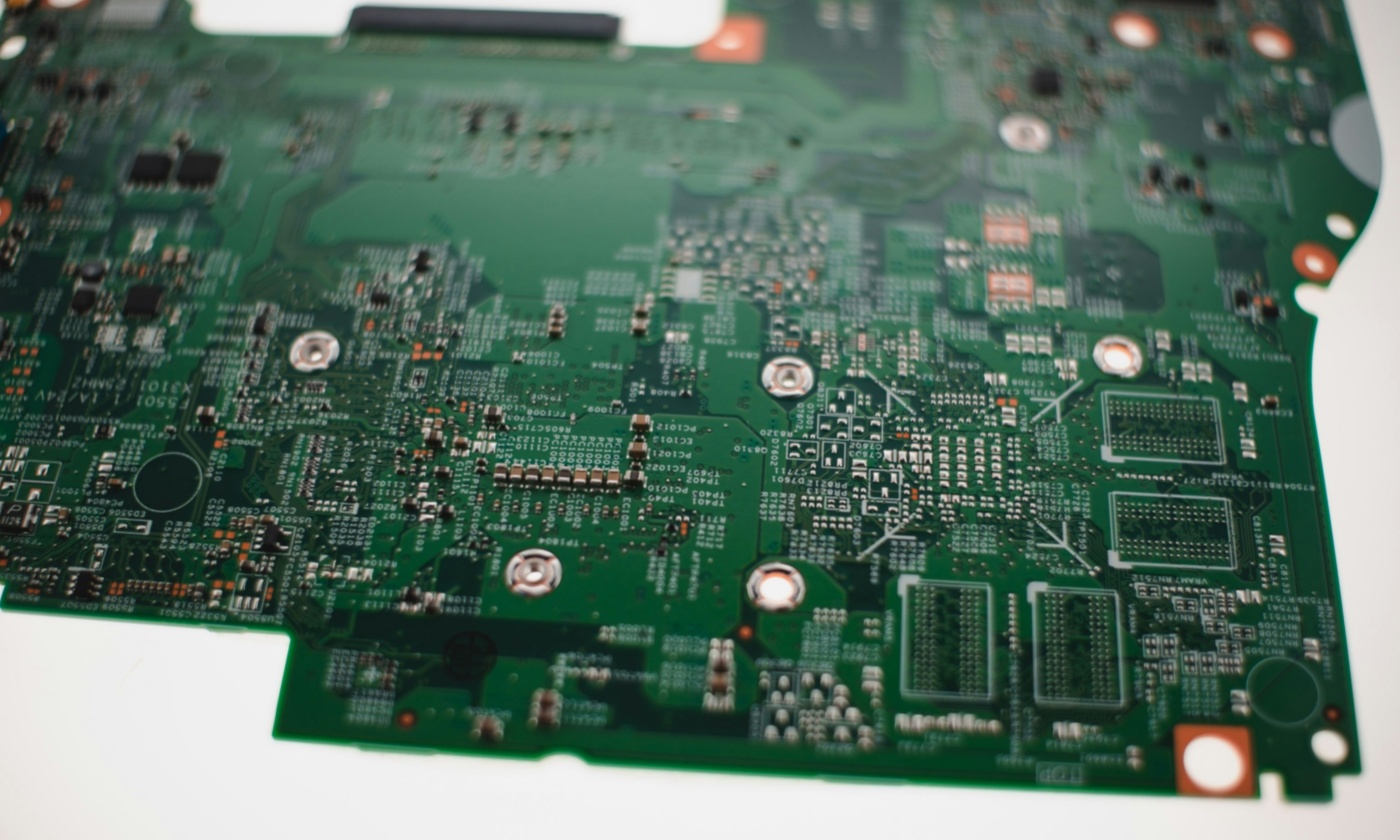

Sodium Persulfate finds extensive use in etching processes, particularly in electronics manufacturing and the semiconductor industry as a micro-etchant. In electronics component fabrication, etching removes excess metal layers to form precise circuit patterns. Sodium Persulfate participates in micro-etching by reacting with metals like copper and aluminum, creating microscopic roughness on the metal surface. This enhances adhesion and bonding in subsequent processes, supporting efficient etching results.

In the semiconductor industry—where etching is a critical step affecting chip performance and reliability—Sodium Persulfate's properties and stability enable it to facilitate micro-etching in complex environments, ensuring chip microstructures meet design requirements. Fujian ZhanHua Chemical's high-purity, consistent Sodium Persulfate products have proven particularly reliable in these applications.

III. Optimization of Sodium Persulfate Micro-Etching Processes

Optimizing Sodium Persulfate micro-etching processes is essential to enhance efficiency and reduce costs:

Concentration & Temperature Control: Adjusting Sodium Persulfate concentration and temperature regulates etching rate and selectivity. Higher concentrations and temperatures accelerate etching, but excessive levels may damage surfaces, requiring careful balancing based on process needs.

Additives: Incorporating appropriate corrosion inhibitors and stabilizers improves etching uniformity and solution stability. Inhibitors minimize etching of non-target areas, while stabilizers extend solution lifespan, lowering costs.

Fujian ZhanHua Chemical focuses on such optimizations in product R&D, offering various Sodium Persulfate specifications to meet diverse customer needs.

IV. Market Prospects and Competition Analysis

With the rapid growth of electronics manufacturing and the semiconductor industry, etching market demand continues to rise, promising a broad future for Sodium Persulfate as a key micro-etchant. While numerous global producers exist, Fujian ZhanHua Chemical stands out for its technical edge and product quality. Its annual Sodium Persulfate production capacity of 50,000 tons—coupled with a Phase III project scheduled for 2026 that will further increase capacity—solidifies its global leadership. The company's comprehensive advantages in technical support, quality, and customer service have also earned it a strong market reputation.

Sodium Persulfate plays an irreplaceable role in etching processes, valued for its unique micro-etching functions and environmental benefits. From electronics and semiconductors to other high-tech fields, it drives etching technology advancements and supports efficient, innovative industrial production. As etching continues to evolve, Sodium Persulfate will remain a cornerstone of modern manufacturing.